This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

- Deep Cleaning Instructions

- Operation and Installation Manual

- Filter Configurations

- Flyer

- Fully Integrated Self-Cleaning Spec Sheet

- NYC Certificate of Approval

- Self-Cleaning Spray Bar Pressure Drop

- Submittal Drawing

- Written Specification (PDF)

- Written Specification (Word Document)

Upgrade your Self-Cleaning hood with our latest technology in fire suppresion

Click here to view the

CORE Fire Suppression System »

The ND-2, SND-2 and BD-2 Models have been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. and Canadian products safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance. Models are ETL listed under file number 3054804-001.

The SCS Model has been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. and Canadian products safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance.

Models SCS are ETL Listed under file number 101754591COL-001 and complies with UL508A Standards and CSA C22.2, No. 14-M95 and CSA C22.2, No. 73-1953 Standards.

Self-Cleaning Hood

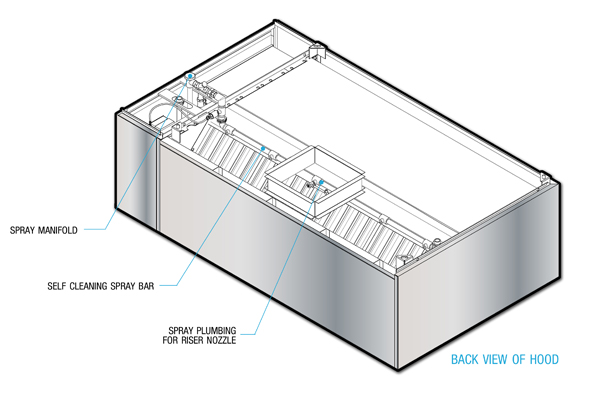

The Self-Cleaning Hood is fabricated from stainless steel and contains a spray bar that extends the full length of the hood immediately behind the filters. The spray bar is fitted with nozzles to ensure adequate spray down of the plenum and back of the filters. A nozzle is located in the exhaust riser to clean a portion of the ductwork as well.

- Fully automatic operation

- Hood fabricated from 100% Stainless Steel

- Drip-less nozzles with internal strainer

- Easily serviceable

- Adjustable wash duration (factory set at 3 minutes)

- 3/4", 1", 1.5" NPT Pipe Water Inlet connection

- 1 1/2" NPT Pipe Water Drain connection

- Standard riser spray nozzle for duct cleaning

- Water usage is 0.70 GPM per foot of hood length

- Upgrade to the CORE Fire System available

- High Efficiency Grease Filtration

The Hot Water option automatically cleans the hood plenum after the cooking operations are completed for the day or via schedule. By washing the plenum while the hood is hot, the effectiveness of the cleaning increases. For a standard application, surfactant will be injected into the wash for one second, every one minute of the cycle. The wash time, the surfactant injection interval, and the surfactant duration is adjusted to meet the needs of every application.

Integral Utility Cabinet option includes the manifold and electrical controls directly mounted into the cabinet on either end of the hood. All piping and wiring are done in the factory to minimize labor at the job site. The manifold size available is 3/4" and covers up to 48 feet of hood, depending on operational water pressure.

SCS Panel (Open View)

Remote Manifold and Controls are available when the design of the application does not allow for a utility cabinet on the end of the hood. The manifold and controls can be ordered in a remote cabinet and piped to the hood at the jobsite. The panel includes a combination pressure/temperature gauge, shock absorber, pressure reducing valve, water solenoid valve, surfactant pump, line strainer, ball valve and surfactant tank.

Features & Benefits

Features & Benefits

- ETL Listed Product

- Easily programmable wash scheduling

- Adjustable wash duration (factory set at 3 minutes)

- 3/4", 1" and 1 1/2" inch manifolds available based on application needs

- Backflow preventer standard

- Multiple Zone Washing

- Adjustable surfactant injection time (1 to 15 seconds)

- Adjustable surfactant frequency (1x, 2x, 4x)

- Factory installed surfactant injection point

The SCS Panel provides plumbing and electrical controls for Self-Cleaning hoods when the design does not allow for a utility cabinet on the end of the hood. The manifold and controls are located in a remote cabinet and piped to the hood at the jobsite. The plumbing assembly includes a combination pressure/temperature gauge, shock absorber, pressure reducing valve, water solenoid valve, surfactant pump, surfactant tank, line strainer and ball valve.

The SCS Control Panel includes a state-of-the-art controller and touch screen for ultimate control of the Self-Cleaning operation. The touch screen interface, located on the front of the panel, allows for user-friendly programming including multiple wash zones and programmable schedule.

The SCS Control Panel provides starter coil control for both exhaust and supply fans and can be ordered in conjunction with an electrical control prewire that includes motor starters.