This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

PARAGON HVAC Unit

Paragon HVAC is designed from its core to conserve energy and save on operating costs. Paragon’s rare earth magnet inverter scroll compressor eliminates excessive cycling, premature unit aging, inefficient hard starts, and unnecessary energy consumption. Paragon’s modulating technologies allow it to deliver the highest efficiencies at part-load conditions.

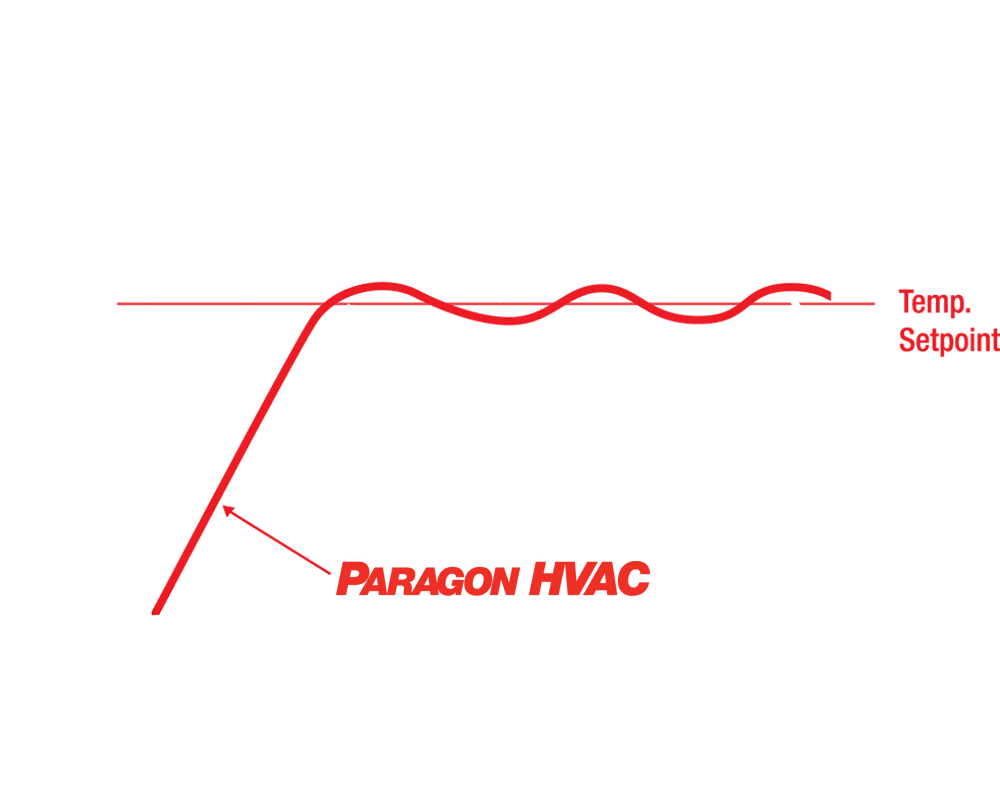

Paragon HVAC contains fully modulating refrigeration and optional hot gas reheat components that deliver the exact amount of air requested at the desired temperature and humidity. Variable speed components allow Paragon HVAC to adjust its heating and cooling capacity to match the required load. This provides a consistent temperature throughout the space and avoids large temperature swings often associated with single stage equipment.

Paragon HVAC achieves an impressive 21.3 IEER rating (Integrated Energy Efficiency Ratio) which is over 1.5x the ASHRAE 90.1-2016 IEER standard. Designed with the future in mind, Paragon HVAC is poised to exceed rising IEER standards for years to come.

Paragon HVAC comes standard with a 5 year parts warranty. An extended 10 year full unit warranty is included at no extra charge when units are maintained with a CASService Preventative Maintenance subscription (terms and conditions apply). Paragon HVAC is designed with sustainability in mind and is built to last up to 25 years.

Quick Ship Emergency Units

Emergency Paragon HVAC units ship in 2-3 days.

Factory provided curb adaptors are pre-gasketed and come with an integrated electrical chase as well as power and communication whips for quick and easy replacement of any RTU brand.

Contact your local sales engineer today to order!

Features & Benefits

Reliable Service & Technical Support

CaptiveAire offers unmatched factory service and technical support through its rapidly expanding nationwide CASService team. Each local service technician undergoes extensive in-house training to ensure your needs are quickly met and problems are thoroughly addressed. Since Paragon HVAC is a fully standardized equipment line, CASService techs are able to stock most replacement parts on their trucks, eliminating long lead times often associated with service visits. Additionally, Paragon HVAC is designed with service in mind, incorporating several convenience features to make support visits as smooth and efficient as possible.

Find Local Service Rep

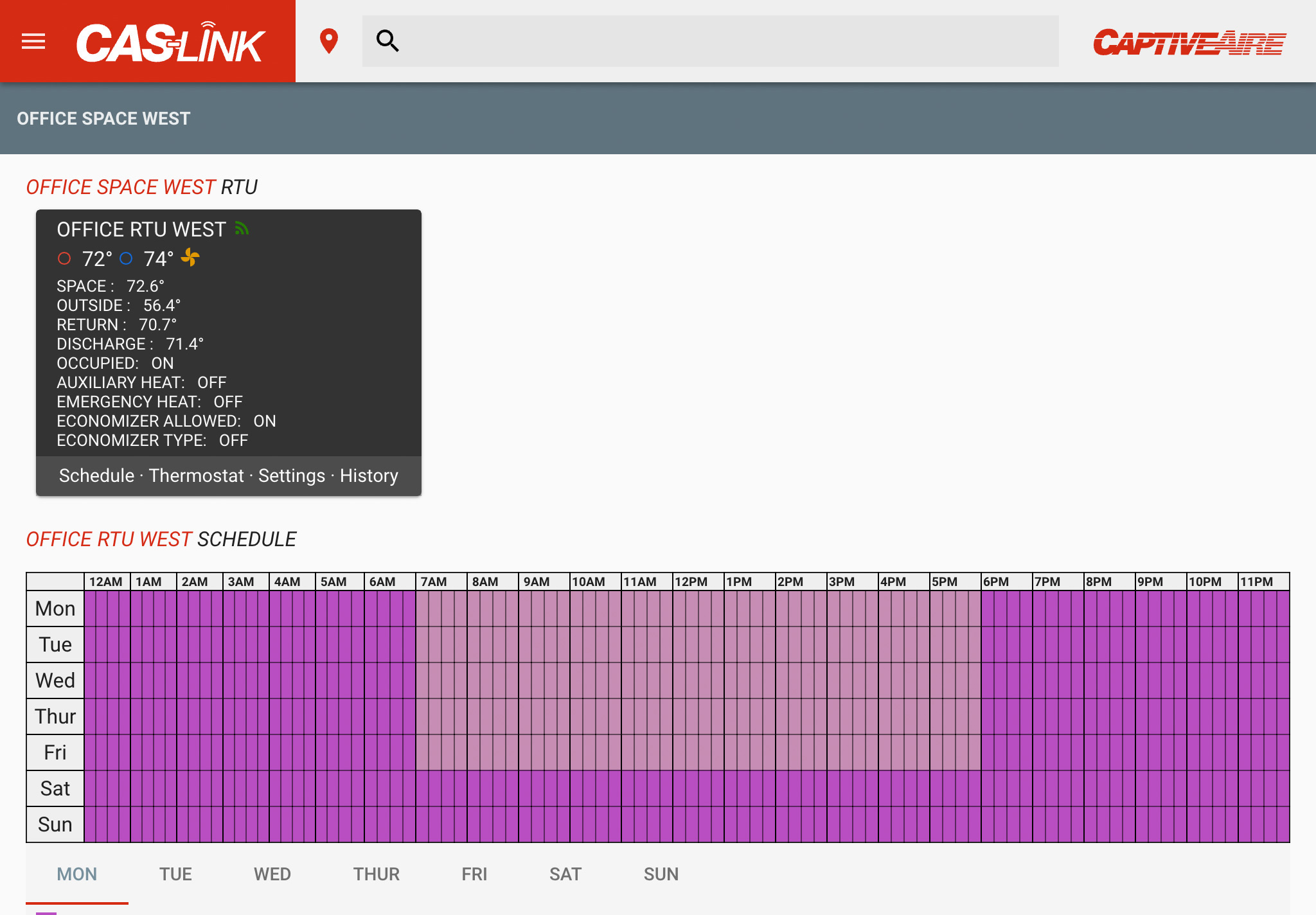

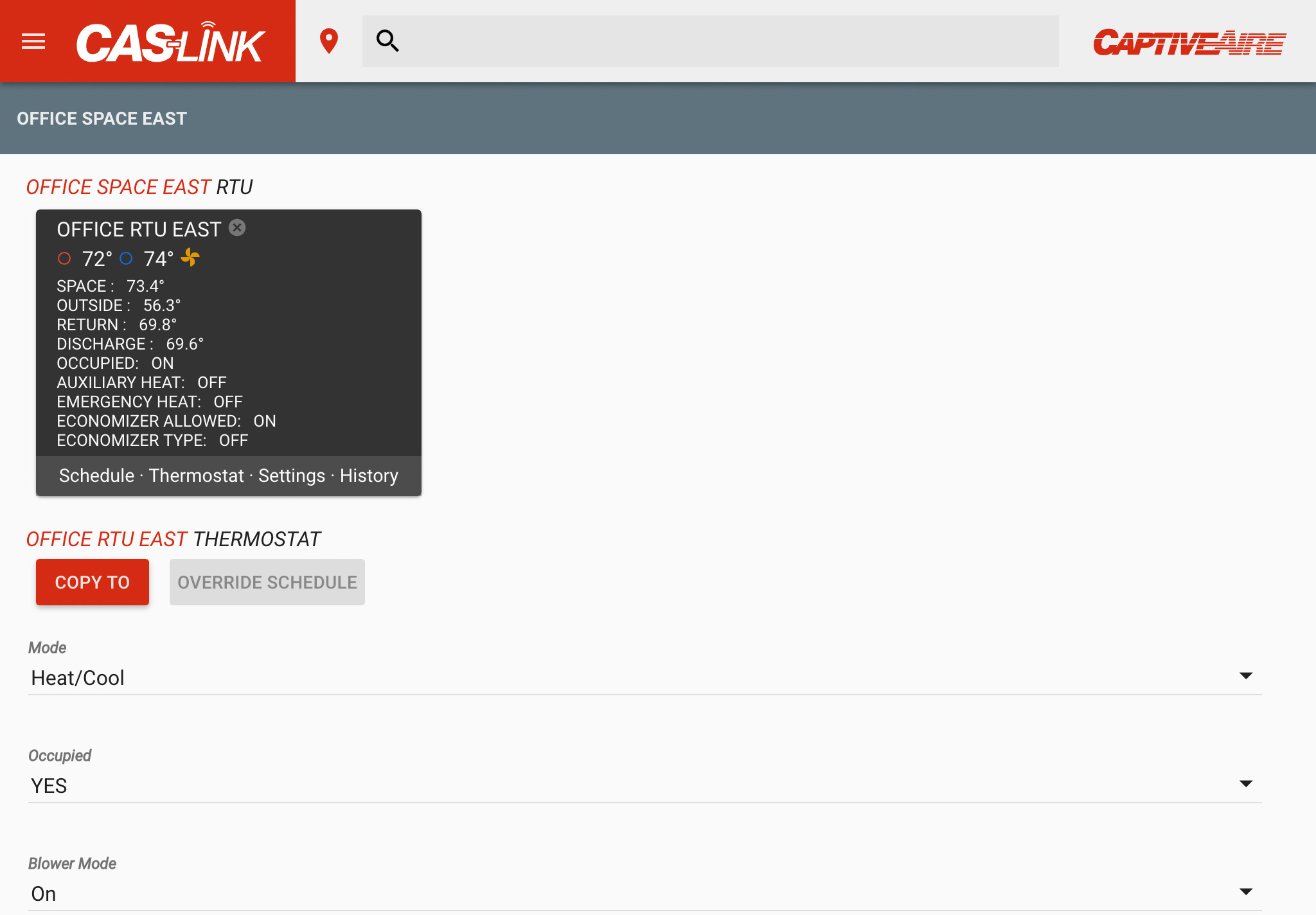

24/7 Real-Time Unit Monitoring

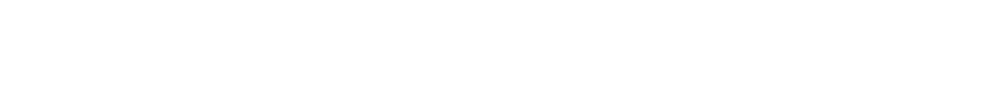

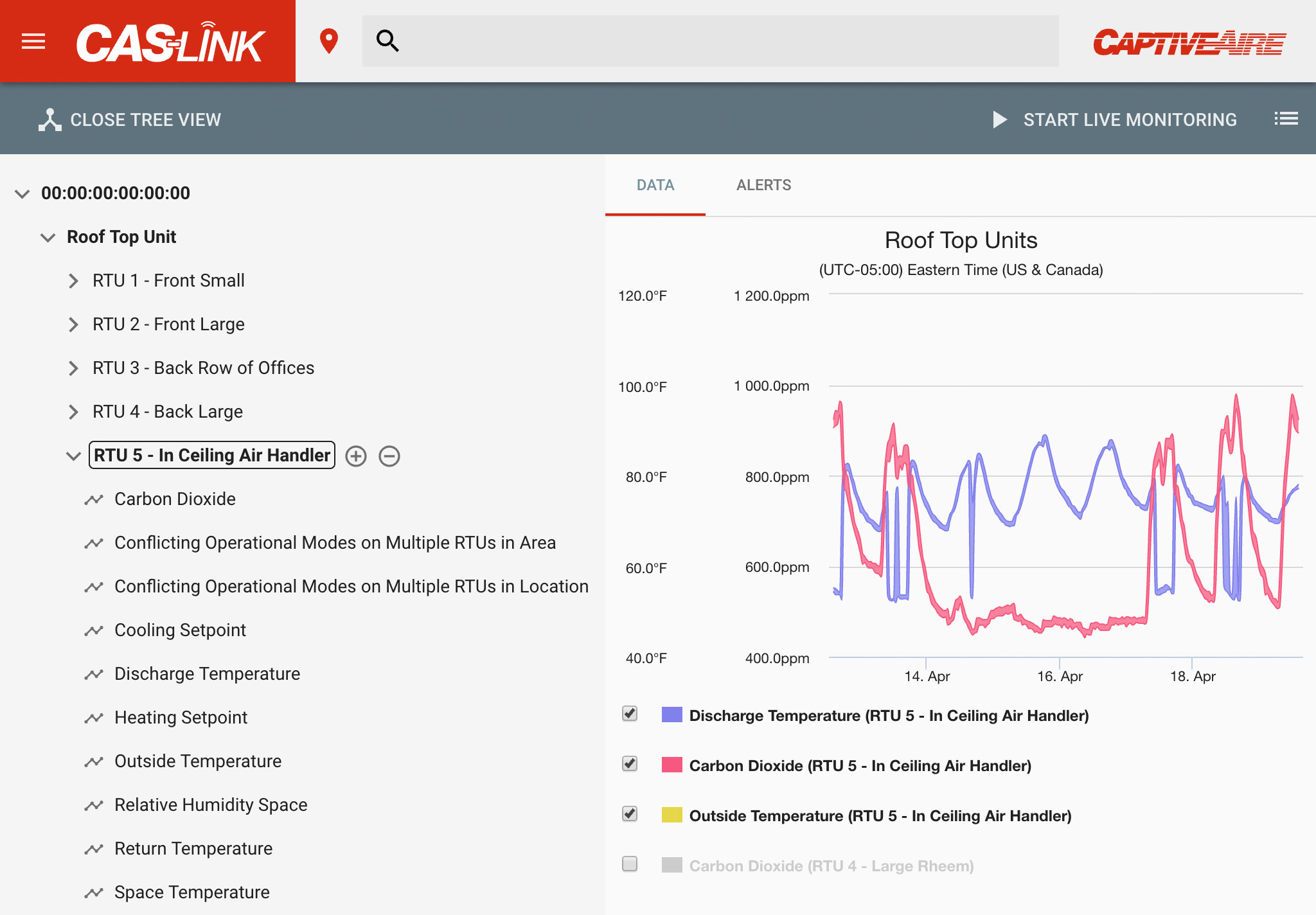

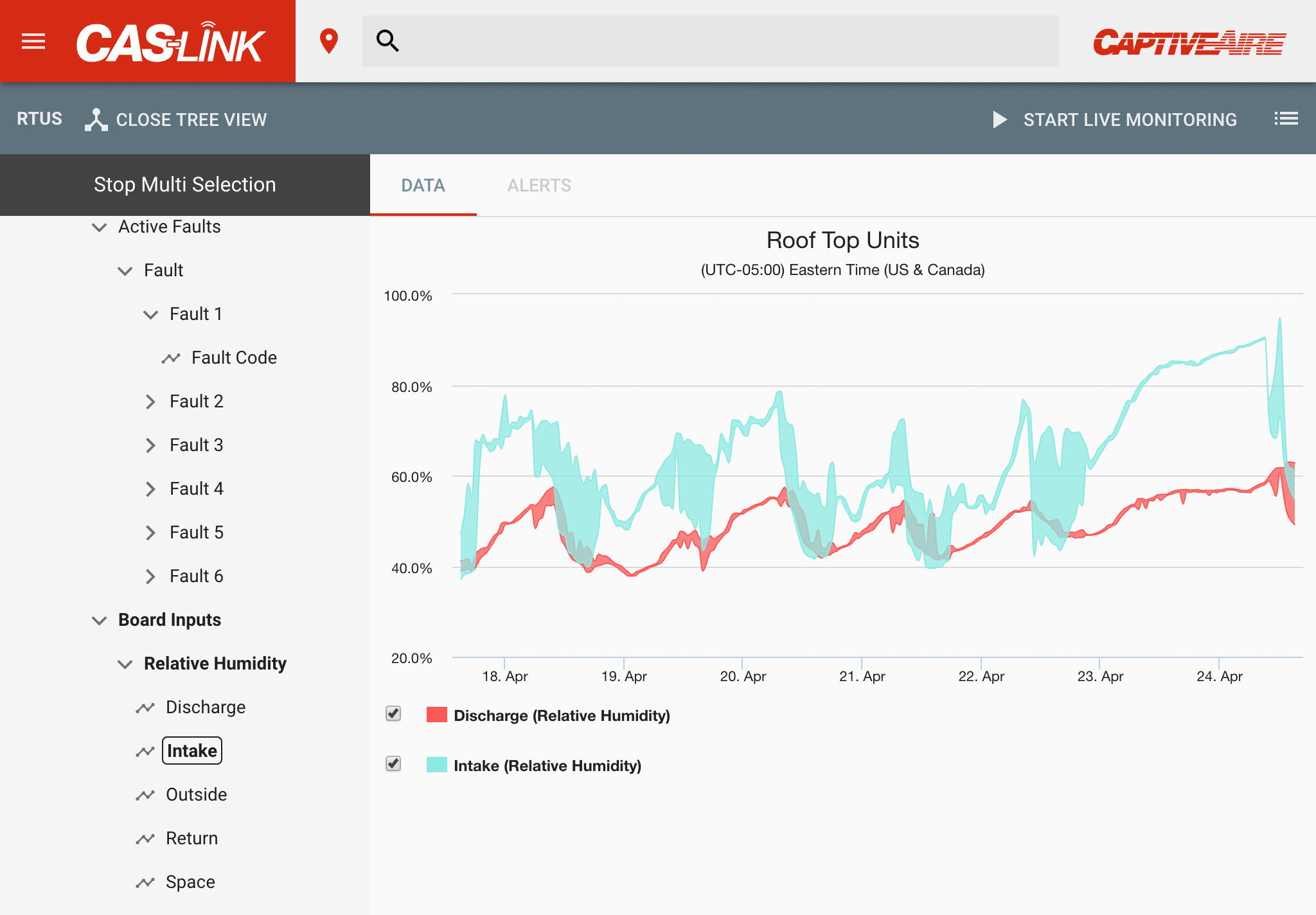

CASLink, CaptiveAire’s proprietary cloud-based building management system, collects real-time performance data in order to verify proper equipment operation, recognize potential problems, diagnose minor issues, and analyze system efficiency. CASLink allows for remote unit adjustments, often eliminating the need for an onsite service tech visit. Every Paragon HVAC includes a CASLink system at no additional charge.

System Sizing and Specifications

| Enclosure Size | 1 | 2 | 3 | 4 | |||||||||||||||||

| Nominal Tonnage | 3 | 4 | 5 | 6 | 7.5 | 10 | 8 | 10 | 13 | 12.5 | 15 | 17.5 | 20 | 25 | 30 | 22.5 | 25 | 30 | 40 | 50 | 60 |

| Min Airflow (CFM) | 500 | 500 | 500 | 600 | 750 | 1000 | 800 | 1000 | 1300 | 1250 | 1500 | 1750 | 2000 | 2500 | 3000 | 2200 | 2500 | 3000 | 4000 | 5000 | 6000 |

| Max Airflow (CFM) | 1200 | 1600 | 2000 | 2400 | 3000 | 3400 | 3200 | 4000 | 4000 | 5000 | 6000 | 7000 | 8000 | 8000 | 8000 | 8800 | 10000 | 12000 | 15000 | 15000 | 15000 |

| Indoor Coil Rows | 4 | 4 | 4 | 4 | 5 | 6 | 5 | 5 | 7 | 6 | 6 | 7 | 7 | 7 | 7 | 5 | 5 | 6 | 6 | 8 | 8 |

| Max Cooling Turndown Ratio | 5:1 | 6:1 | 7:1 | 7:1 | 7:1 | 7:1 | 7:1 | 7:1 | 7:1 | 6:1 | 7:1 | 6:1 | 7:1 | 7:1 | 7:1 | 7:1 | 14:1 | 17.5:1 | 14:1 | ||

| IEER | 17.9 | 17.9 | 17.9 | 19.5 | 18.6 | – | 20.2 | 18.6 | – | 21.3 | 18.8 | 18.2 | 18.2 | 14.9 | 14.9 | 18.1 | 17.9 | 17.8 | 16.6 | 17.1 | 17.0 |

| ISMRE2 | 5.40 | 6.94 | 6.45 | 7.21 | 7.31 | 6.23 | 7.26 | 7.30 | 5.84 | 7.09 | 8.31 | 7.97 | 7.87 | 4.97 | 5.76 | 6.28 | 6.81 | 8.10 | 7.33 | 7.20 | 7.53 |

| Max Heating Turndown Ratio* | 20:1 | 20:1 | 20:1 | 17:1 | 14:1 | 12:1 | 21:1 | 16:1 | 13:1 | 25:1 | 16:1 | 16:1 | 16:1 | 16:1 | 16:1 | 18:1 | |||||

| Furnace Input Capacity (MBH) | 50 - 260 | 50 - 440 | 150 - 685 | 200 - 1100 | |||||||||||||||||

| Electric Coil Capacity (kW) | 10 - 60 | 15 - 60 | 15 - 100 | 30 - 240 | |||||||||||||||||

| Curb Size (L x W) | 71" x 41" | 75" x 49.5" | 91" x 59.5" | 111" x 80" | |||||||||||||||||

| Unit Dimensions (L x W x H) | 77.25" x 62" x 47.5" | 81.75" x 80.75" x 60.75" | 99" x 89.75" x 69" | 174" x 89.75" x 94" | |||||||||||||||||

| Approximate Weight (lbs) | 1000 - 1250 | 1650 - 1800 | 2400 - 3600 | 4250 - 7500 | |||||||||||||||||

| *Contingent upon heat source | |||||||||||||||||||||

Product Resources

Cooling & Heat Pump Information

Additional Information

- Paragon HVAC Brochure

- Operation & Installation Manual - MUA Controls (Current)

- Operation & Installation Manual - MUA Controls (Current) (French)

- Operation & Installation Manual - IBT Controls (Legacy)

- DDC Application Guide

- Paragon User Guide

- Electric Insert Specifications

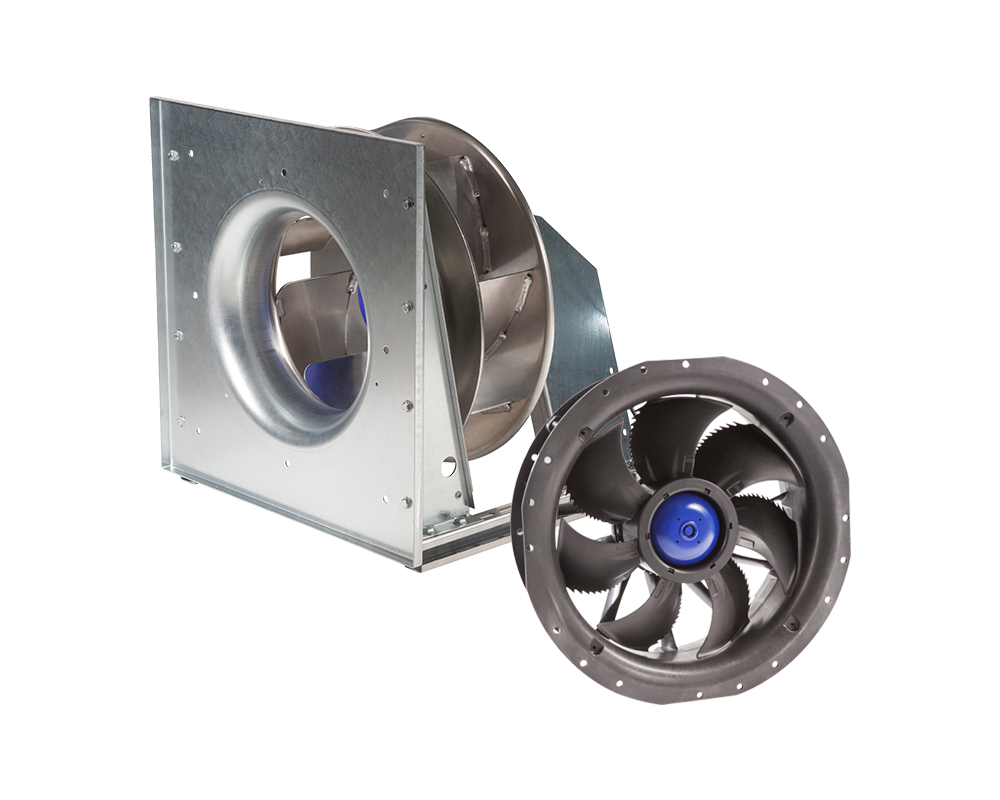

- Supply Fan Performance Data

- CaptiveAire HVAC Unit Specifications (PDF)

- CaptiveAire HVAC Unit Specifications (Word)

Achieve Air Quality Excellence

Earn certification through CaptiveAire and receive a front door decal and a plaque for your lobby.

Your patrons will breathe in confidence knowing the air they breathe is healthy and fresh.

Learn More about AQE