This site is protected by reCAPTCHA and the Google Privacy Policy and Terms of Service apply.

Fully Integrated Package

CaptiveAire sells this hood as a stand-alone appliance to be integrated into a kitchen ventilation application, or provided as part of a FULLY INTEGRATED PACKAGE designed by CaptiveAire and pre-engineered for optimum performance. The package consists of the hood, an integral utility cabinet, factory pre-wired electrical controls, and a listed fire suppression system. Other options include a listed exhaust fan, a listed make-up air unit and listed, factory-built ductwork.

Drawings

Additional Information

- Deep Cleaning Instructions

- Backsplash Installation

- Frequently Asked Hood Questions

- Fully Integrated Self Cleaning System Option

- NYC Certificate of Approval

- Operation & Maintenance Manual

- Operation & Maintenance Manual (Spanish)

- Operation & Maintenance Manual (French)

- Request Product Information

- Test & Balance Spreadsheet - Shortridge (PC)

- Test & Balance Spreadsheet - Evergreen (PC)

- Written Specification (PDF)

- Written Specification (Word Document)

Certifications

The ND-2WI Model has been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. and Canadian products safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance.

Models ND-2WI are ETL Listed under file number 102900319PRT-001 and complies with UL710, ULC710 and ULC-S646 Standards.

The ND-2WI Series is a Type I, Single Island Hood for use over 450°F, 600°F and 700°F cooking surface temperatures. Single island hoods are used over cooking equipment where no walls exist or for display cooking.

Fully Integrated Package

CaptiveAire sells this hood as a stand-alone appliance to be integrated into a kitchen ventilation application, or provided as part of a FULLY INTEGRATED PACKAGE designed by CaptiveAire and pre-engineered for optimum performance. The package consists of the hood, an integral utility cabinet, factory pre-wired electrical controls, and a listed fire suppression system. Other options include a listed exhaust fan, a listed make-up air unit and listed, factory-built ductwork.

Advantages

- ETL Listed: ETL Listed for use over 450°F, 600°F and 700°F cooking surface temperatures, which provides flexibility in designing kitchen ventilation systems. ETL Listed to US and Canadian safety standards, ETL Sanitation Listed and built in accordance with NFPA 96.

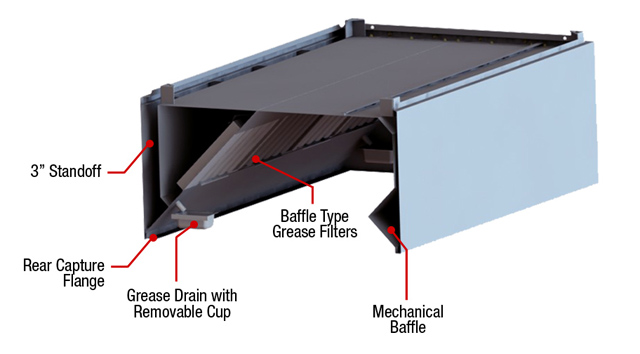

- Capture and Containment: Insulated, double-wall rigid front has aerodynamic design that reduces radiant heat into kitchen, prevents condensation and provides exceptional capture and containment of cooking vapors. Rear capture flange to help aid in the capture and containment of heat and effluent generated by cooking process.

- Construction: Construction shall be Type 430 stainless steel with option of Type 304 available. Fully welded and polished corners. All four sides of the hood will be finished sides. Hood shall include a rear flange to improve capture efficiency.

- Controls: Hoods can be equipped with modular utility cabinets and end standoffs. Optional listed light and fan control switches flush mounted and pre-wired through electrical chase way.

- Convenient Design: Factory pre-wired lighting to illuminate the cooking surface is accessible from the bottom of the hood. Fitted with UL Listed, pre-wired, incandescent light fixtures and tempered glass globes to hold up to a standard 100 watt bulb. Pre-punched hanging angles on each end of hood and additional set provided for hoods longer than 12'.

- Grease Extraction: All hoods come standard with stainless steel baffle filters and a deep grease trough which allows for easy cleaning. Captrate Combo® and Captrate Solo® filters are optional. Grease drain system with removable 1/2 pint cup for easy cleaning. Standard filter stops eliminate gaps between filters.

- Reduced Lead Times and Shipping Costs: Produced on a high volume assembly line at one of six manufacturing facilities to reduce lead times and shipping costs.

- Optional Make-Up Air: Make-up air can be supplied through optional front and/or side plenums (ND-2WI Series with PSP or AC-PSP Accessory).

- Optional Self Cleaning Technology: The Self Cleaning Hood option adds a spray bar that extends the full length of the hood immediately behind the filters. The system cleans grease from the plenum and portion of the duct with the daily hot water spray cycle.

- Optional CORE Protection: The CORE Fire Protection System is an automatic, pre-engineered fire suppression system which is ETL listed to UL Standard 300. The CORE Protection System is designed to provide primary coverage for ventilating equipment including hoods, ducts, plenum and filters.

- Optional Heat Recovery Coil: This option is available for hoods with CORE Protection. A listed coil accessory can be added to the hood plenum to recover heat from the exhaust stream. Warm air in the exhaust stream passes over the coil and heats the cold water in the coil, acting as a preheater on the hot water supply line for the restaurant or facility.

Performance

| Avg. Cooking Surface Temp. (°F) | Configuration | Min. Exhaust CFM/ft. |

|---|---|---|

| 450°F | Single Island Hood | 269 |

| 600°F | Single Island Hood | 300 |

| 700°F | Single Island Hood | 350 |

Recommended Duct Sizing: Exhaust - Based on 1500 FPM

Features

Optional Vertical End Panels (VEP & WVEP)

Energy Savings

- VEPs provide improved capture and containment by directing effluents into the hood and blocking cross drafts

- Allows exhaust CFM reductions up to 18%

- Equivalent reduction in makeup air

- This saves on fan energy, make-up air heating/cooling energy

- Possible equipment downsizing, reduces upfront cost

Design

- Stainless steel matches hood finish

- Gas chase allows appliance lines to run between wall and end panel

- Double-wall insulated construction

- Adjustable feet

- May allow for a reduction in required side overhangs

Safety

- Encloses the hood area, preventing flames or embers from escaping

- Ensures equipment is not accidentally moved outside of the hood area

- Stainless steel construction for sanitation and longevity

- Legs raise bottom of panel off floor to allow room for cleaning

- Hemmed edges prevent sharp surfaces

- Wide Vertical End Panels (WVEPs) provide an increased level of heat containment and fire protection, especially useful for high radiant load appliances such as solid fuel

Options

Utility Cabinet: Utility Cabinet: Listed for integral side mount and fabricated of same material as hood. Cabinet can house listed fire suppression system and listed, pre-wired electrical controls.

Perforated Supply Plenum: Provides low velocity make-up air for the kitchen and is discharged in front, back or sides of the hood. Perforated diffuser plates allow for even air distribution and supply riser includes a volume damper for easy balancing. Side Perforated Supply Plenums can be added to optimize the air flow if necessary.

Enclosure Panels: Constructed of stainless steel. Sized to extend from hood top to ceiling, enclosing pipe and hanging parts.

End Panels: Should be used to maximize hood performance and eliminate the effects of cross drafts in kitchen. Units constructed of stainless steel and sized according to hood width and cooking equipment. Exposed edges hemmed for safety and rigidity.

Roof Top Package: Combination ETL Listed exhaust/supply air unit with factory prewired and mounted motors, trunkline and curb vented on exhaust side.

Separate Exhaust and/or Make-Up Air Fans: ETL Listed single exhaust fan, supply-air fans and curbs available.

Fire Suppression System: UL 300 fire suppression system.

Lighting: Recessed Incandescent, Recessed Fluorescent, Compact Fluorescent, Recessed LED, Halogen

General Maintenance

Certifications

The ND-2WI Model has been certified by ITS. This certification mark indicates that the product has been tested to and has met the minimum requirements of a widely recognized (consensus) U.S. and Canadian products safety standard, that the manufacturing site has been audited, and that the applicant has agreed to a program of periodic factory follow-up inspections to verify continued performance.

Models ND-2WI are ETL Listed under file number 102900319PRT-001 and complies with UL710, ULC710 and ULC-S646 Standards.